Fiat Press Information For The UK Launch - 7th December 1995 The following information is from the press information pack given out to motoring journalists at the UK launch of the Bravo and Brava in December 1995. This was not released to the general public until now! Page down to the bottom for adverts and road test information.

Already the subject of widespread customer demand and resounding critical acclaim -including the prestigious 1996 European Car of the Year Award - the all-new Fiat Bravo and Fiat Brava go on sale here in right-hand drive at the end of December. Designed and developed to reflect the desires and requirements of today's motorists, Bravo and Brava exhibit features that distinguish recent Fiat Auto production, including strong, personal styling; state-of-the-art engines with outstanding performance, reliability and low running costs; responsive handling; comfort and practicality in even the smallest detail, and the highest safety standards. Bravo is a sporty two-box, three-door compact destined primarily for a youthful public. Brava is a dynamic, practical five-door 'fastback', which is extremely roomy and comfortable. A completely new range of multi-valve engines makes its debut at the same time. These are two different models with a common design base, setting new standards in the medium saloon bracket (known as C-segment), which currently accounts for some 30% of the European market (3.5 million cars). Not surprisingly, it's an area in which all major manufacturers compete, with the result that it is viewed as perhaps the most competitive segment of the entire European market. For Fiat Auto the arrival of Bravo and Brava represents an important new challenge, just two years after the launch of the Punto. These two new vehicles are the outcome of an extensive renewal and growth that has been taking place in Fiat Auto over the past five years. A bold investment plan launched early in the nineties envisaged expenditure of some 40,000 billion lire, over 70% of which is already accounted for. It has resulted in new models for every sector of the market, a return to the convertible and coupé markets, an entry in the people-carrier segment, the creation of innovative facilities at Melfi (an integrated car manufacturing plant) and Pratola Serra (automated production of engine 'families'), and the refurbishing of others, with the introduction of the integrated factory concept throughout Fiat Auto's industrial network. Fiat Auto has set its sights firmly on Europe, convinced of the need to create and market cars with a European character in terms of reliability, safety, quality and respect for the environment, but with an Italian flair where styling and driving enjoyment are concerned. This cultural and industrial revolution has brought significant results; from the success of the Punto in Europe (over one million manufactured), to Fiat Auto's increased share of EU markets - in the first half of 1995 the Italian group recorded the largest sales increase among large European manufacturers. Fiat Bravo and Fiat Brava called for an investment of some 1,500 billion lire, while development of the engines accounted for over 2,000 billion lire. It is the first time in Fiat Auto's history that two models, with complementary origins and components but different dimensions, designs and targets, have been launched simultaneously. This is a philosophy that extends customer choice and offers a real alternative in the many versions of the Fiat Bravo and Fiat Brava. These two new cars are a further step in Fiat's dramatic rebirth. Designed by an interfunctional team of 200 specialists working with simultaneous engineering techniques -a process adopted for the Punto - they entered production after just 32 months, and 3.5 million hours of work. They are built in the refurbished Cassino factory, but some production also takes place in the Rivalta plant outside Turin. The names, Bravo and Brava - similar but not identical - underline the cars' Italian origins and different personalities. Bravo and Brava project the core values of the European car, combining them with originality, styling and creativity typical of their country of origin. This is a combination that has produced new, innovative cars from all viewpoints, with fresh, personal styling, performance and driveability that stand the test of roads and traffic, and an excellent level of comfort that is derived from their structural integrity. Developed in the Fiat Styling Centre, the design of the Fiat Bravo and Fiat Brava was inspired by natural shapes, and refined by painstaking aerodynamic research to keep noise to a minimum (the Fiat Bravo has a Cd of 0.32, and the Fiat Brava a Cd of 0.33). The effect is not one of 'collage' but a single image, enhanced by the matching of fixed and mobile parts (doors, tailgate, bumpers/wings), the absence of sharp edges, and smoothly curving surfaces.

The styling is lively, fluid and muscular, conveying a sense of safety, solidity and quality. The Fiat Bravo and Fiat Brava share certain elements, like their tapering sides, large window areas flush with the body, and large wrapround bumpers. The Fiat Bravo stands out for its compact profile, muscular flanks, original elliptical lighting clusters, and truncated tail; the Fiat Brava for its small rear overhang, arched roof, and gem-shaped light clusters. As for the Punto, colour is used to highlight the innovative elegance of the Fiat Bravo and Fiat Brava. Two separate ranges underline the cars' different personalities: brighter, more assertive tones on the Bravo (11), more elegant, classical shades for the Brava (13). The interiors meet the latest ergonomic and space criteria, featuring soft lines, a homogeneous design of all details, and great attention to every element: from the ash tray to the boot release. The result is a well furnished interior, with basic measurements larger than those of previous Fiat models. The Fiat Bravo and Fiat Brava are the result of an advanced project designed to ensure dynamic handling and roadholding. Fundamentals include a five-speed gearbox, independent suspension, twin cross-over braking circuits, the option of ABS, standard equipment power steering, and bodyshells with class-leading torsional rigidity. Three new multi-valve petrol engines become available in the UK at the cars' launch: 1400cc with 12-valves and 80 bhp; 1600cc with 16-valves and 103 bhp; 1800cc with 16-valves and 113 bhp. They will be joined in the UK by powerful new intercooled turbo-diesel versions next year, together with an automatic transmission version, and a five cylinder 20-valve 2-litre petrol version of the Bravo. The 1400 and 1800 engines belong to the new generation of modular Fiat power units manufactured in Pratola Serra. The 1600 Torque engine, so-called because of its particularly generous torque delivery, is built in Fiat Auto's Mirafiori plant, and is also new. All the engines feature high specific power, impressive fuel economy, flexibility, low maintenance requirements and quiet running, thanks to Fiat Auto's advanced manufacturing processes. The Fiat Bravo and Fiat Brava also lead the field where passive safety and environmental protection are concerned. Features include a bodyshell reinforced to EU 1998 standards, side impact beams, pretensioned seat belts, anti-intrusion beam on split rear seats, energy absorbing steering, fire prevention system, standard equipment driver airbags, and the Fiat CODE electronic security key. The engines meet EU 'Phase 2' (1997) emissions standards, and no elements harmful to the environment are present during manufacture or on the cars, which are built to be fully recyclable at the end of their working lives. Bravo and Brava went on sale in Italy on 16 September. Some idea of the impact these cars have already made can be gauged from the fact that on this weekend alone, (16/17 September), more than 3 million Italians took the opportunity to view the cars at Fiat Auto's 2200 sales outlets. Some 125,000 visitors took a test drive in the 35,000 demonstration vehicles available, and no less than 88,500 registered with their dealers as potential customers. Less than two months after its introduction in Italy, and barely one month after it went on sale in most of mainland Europe, 130,000 orders for the two new cars had been taken by dealers. Some 90,000 Fiat Bravos and Bravas will have been delivered to customers by the end of 1995.

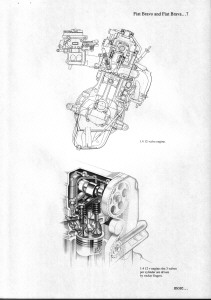

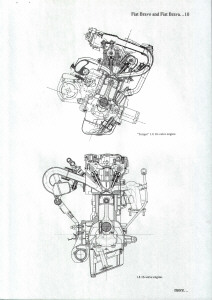

DRIVING PLEASURE Engines Four brand new petrol engines made their debut with the Fiat Bravo and Fiat Brava. They already conform to EC 'Phase 2' standards on exhaust emissions control, due to come into force in January 1997 for newly registered cars. Each engine is fitted with an aluminium alloy multi-valve head and is produced using the most sophisticated computer technology, from the first stage of CAE (Computer Aided Engineering) design to the final stage of quality control. Each is a carefully balanced amalgam of high power, low fuel consumption, lasting dependability and simple maintenance requirements. Three of the engines belong to the modular family produced in Fiat Auto's new Pratola Serra factory, which is equipped with the most modem technologies and capable of turning out 3600 units a day in eight different configurations of modularity. The fourth, the so-called Torque unit, a 1581 cc engine, is manufactured in Turin and has rational design and production in common with them. The range is capable of meeting the most diverse demands in terms of running economy and performance. The 1.4 12-valve engine Aimed at a broad user category, this unit puts the onus on economical running and refinement, without losing anything in the way of verve. It is a four cylinder in-line unit (1370 cc, 80 bhp-EC at 6000 rpm) with 3-valves per cylinder and a single overhead camshaft driven by a toothed belt. It boasts self-adapting SPI Monomotronic Bosch integrated electronic management with active knock control, hydraulic tappets and an automatic belt tensioner. In detail: - the presence of three valves per cylinder

(two for induction, one for exhaust) ensures high levels of performance,

but using simplified and lighter weight timing gear; Finally, for lasting and total reliability the engine has a self-adapting electronic control unit capable of recognising progressive adjustments of the engine, reoptimising the main control parameters and eliminating emissions and performance drift throughout the engine's life cycle. It also has active knock control, whereby it is possible to recognise the phenomenon of detonation and adjust ignition advance to compensate for irregularities inside or outside the engine, and hence to restore optimal combustion conditions. The Torque 1.6 16-valve engine This is a technically sophisticated four cylinder in-line 1581 cc unit which delivers 103 bhp-EC at 5750 rpm and 106 lb.ft of torque at 4000 rpm. Its distinctive feature is a 4-valves per cylinder head with twin overhead camshafts driven by a toothed belt. Hydraulic tappets for automatic valve clearance adjustment and an automatic timing belt tensioner are also fitted. The engine has a notably efficient torque curve - hence its name - with as much as 90% of peak torque available between 2500 and 5500 rpm. Special care was taken in the development of this unit to optimise fluid dynamics. CAD-CAE mathematical computer simulation programmes were used to define the shape and dimensions of the intake and exhaust manifolds to optimise the mixing and division of the fuel/air split among the cylinders. The same amount of care was also devoted to the design of the combustion chambers, whose geometry was defined to reduce harmful exhaust emissions to a minimum and to optimise combustion, and to the design of the cylinder head cooling circuit, the efficiency of which is fundamental for lasting reliability. Other interesting features are: - the 'long branch' (400 mm) geometry of

the intake manifold, ensuring an optimal delivery curve at low

and medium RPM. Highly innovative casting and machining

process techniques were used to build some of the components.

For example: The 1.8 16-valve engine Like the other units in the new family, this engine (1747 cc, 113 bhp-EC at 5800 rpm) has been designed to ensure maximum efficiency in terms of low fuel consumption, low exhaust emissions and high power, as well as easy maintenance and notable refinement. Its dimensions are, effectively, square (82 x 82.7). This means not only high thermal efficiency, thanks to the compactness of the combustion chambers and the low surface/volume ratio, but also excellent volumetric efficiency, thanks to the adoption of generously sized valves and optimised manifold design. Refinement is ensured by a crankshaft with eight counterweights; a torsional damper fixed to the end of the crankshaft; and a cast aluminium alloy oil sump with a structural function. The ignition system is fitted with an active, selective knock control system: by maintaining ignition advance close to knocking without it actually taking place, the system ensures optimised performance with minimum fuel consumption. The fitting of single coils immediately above the spark plugs avoids dispersion: this is why there are no high voltage cables inside the engine compartment. The phased sequential injection system has single-jet fuel injectors. Like the other engines in this new family, the 1.8 1 6v has hydraulic tappets and automatic tensioning of the timing belt and poli-V auxiliaries control belt to compensate for variations in tension caused by changes from ambient temperature to running temperature, and by the load imposed by accessories. Colour Range Fiat Bravo and Fiat Brava are complemented by their respective colour ranges. Visually exciting, these stress the different personalities of the two cars. Each has a carefully researched and defined range of its own, but the ranges are clearly, visibly interrelated as part of a single chromatic system. The Fiat Bravo comes in the 'louder', crisper colours of a compact sporty car in tune with the tastes of younger buyers. The colours chosen for the Fiat Brava are comparatively 'classic' and sober, as befits a fastback designed for users with more traditional tastes.

Some of the colours have been dedicated to leading names in the history of Italian architecture, the architects who designed the buildings which give Turin, Fiat Auto's headquarters since 1899, its present-day appearance. Transmissions Fiat Bravo and Fiat Brava transmissions have been engineered to ensure consistent handling and precision, and to minimise noise without increasing fuel consumption. The gearbox linkage mated with the 1.4 1 2v engine employs a 'hybrid' arrangement -that's to say flexible cable engagement and rigid rod selection. The gearboxes mated with the other engines have a rigid rod control configuration. Other features - from the damping double wall structure of the central control rod, to the noiseproof coating on the lever fulcrum, and the vibration-proof bushing on the driving gear in proximity to the gearbox - are designed to ensure refinement. Chassis Fiat Bravo and Fiat Brava have independent suspension, twin crossover braking circuits and power steering as standard equipment on all versions. The MacPherson strut front suspension, which incorporates an anti-roll bar and telescopic hydraulic dampers, has offset coil springs, which avoid friction on the suspension and thus improve comfort; the end-of-stroke plates and pads are also optimised to reduce noise during running. High-resistance, forged steel wishbones are fitted, to reduce unsprung weight. They are inclined 50 to ensure an antidive effect and are anchored to an auxiliary crossmember. The steering axis has a 30 angle of incidence for greater agility during parking manoeuvres, and for greater stability at high speed. The independent rear suspension employs trailing arms secured to the body through a rigid frame. The many advantages of this choice of build include the reduction of unsprung weight to improve grip; reduced weight of the suspension for better stress absorption, and the elimination of roll vibration and the transmission of noise to the cabin. The rear suspension is designed to be compact in size, allowing Fiat Auto's designers to incorporate a more uniform boot shape and a larger fuel tank. Flexible suspension mounting to the body allows a slight rear wheel steering effect, giving sharper handling. The main components of the rear suspension are gas-filled dampers, coil springs and lightweight, high-strength, cast iron trailing arms. These arms are mounted to the hub and the braking unit, the latter housing the ABS sensor. An anti-roll bar is mounted to the ends of the arms. Finally, a rigid 'H' frame is used, consisting of a transverse tubular element with two pressed steel side members welded to it; the frame is anchored to the body with special flexible damper mountings to further reduce the transmission of vibration to the body and to offer maximum resistance in the event of accidents. Braking system This has a twin crossover circuit. Thus, if one of the two branches of the system were to fail, controlled braking is still possible on both sides of the car, since each circuit operates on one front wheel and the diagonally opposite rear wheel. In practice it is always possible to maintain control of the car when braking. In addition, the anti-dive geometry distributes the braking loads carried by the front wheels to the rear wheels as well, and thus keeps the car correctly balanced. All versions of the Fiat Bravo and Fiat Brava have front discs and rear drums, with the exception of the high-performance 2.0 version which uses disc brakes on all four wheels. Front brake discs have a diameter of 257 mm when teamed with the 1.4 1 2v and 1.6 16v engines, and are of the same diameter but in a ventilated version with the 1.8 16v engine. All ensure efficient braking and prompt response in line with the performance of the engines. The components used are Teves front brake calipers, featuring two-stud centring and protected guides with self-lubricating rubber slide bushing. The two studs ensure effective, silent braking, while the protected guides ensure its lasting reliability. Rear drum brakes have self-centring shoes and automatic clearance adjustment; with a diameter of 180 mm on the 1.4 1 2v, and 203 mm with other engines. All versions include a pad wear indicator, and employ ecological linings (asbestos-free). An eight inch brake servo with optimised characteristics operates in conjunction with an automatic brake adjuster on the 1.4 1 2v, allowing correct apportioning of the braking effort on the rear wheels. A brake compensator on other versions allows the braking effort to be split in relation to load. Pedals and kinematic mechanisms are designed to allow reduced pedal stroke with low effort and easy modulation. The handbrake is precise to use and quiet in operation. Thanks to automatic clearance adjustment, the stroke stays constant throughout the rear brakeshoes' life cycle, and adjustment is thus unnecessary. ABS anti-lock brakes are available as an option throughout the Fiat Bravo and Fiat Brava range, and are standard on the Fiat Bravo 1.8 HLX and Brava 1.8 ELX. The system adopted is a four-sensor ITT-Teves type with built-in electronics. The electro-hydraulic system consists of a central electronic unit which receives data collected by speed sensors and controls the electro-valves in the hydraulic unit. An hydraulic unit incorporates eight hydraulic electro-valves with two positions, and a scavenge pump recirculates the oil discharged by the circuits when the system is running. The advantages of this solution are reduced weight and size (the electrohydraulic unit fits into a space of less than l6xlOxlO cm); a consequent simplification of the layout of the engine compartment; and high reliability thanks to the adoption of a single main wiring system. Steering The Fiat Bravo and Fiat Brava use two different steering configurations. All versions have rack and pinion power steering as standard; but it is available in two settings according to the version ordered. Its specifications are:

Both settings have been designed to be as noiseless as possible, thanks to baffles in the high-pressure hoses. The power steering valve is also optimised to reduce noise to a minimum during parking manoeuvres; and the introduction of a power steering oil cooling circuit, besides ensuring reliability by subjecting the power steering system to lower thermal stress, also avoids the phenomenon of oil emulsion at high temperatures, with obvious benefits in terms of noise reduction. Bodyshell The torsional rigidity of the two new bodies is another factor which enhances the handling of the Fiat Bravo and Fiat Brava, contributing significantly to their roadholding abilities and stability, especially in terms of ride refinement. Figures of 80,500 daN/rad for the Fiat Brava and 102,600 daN/rad for the Fiat Bravo put both cars at the top of their class. Durability Materials for the bodyshell of the Fiat Bravo and Brava are chosen with a view to achieving an excellent quality standard so as to offer a product that has lasting quality. Some 60% of the weight of the bodyshell is made of galvanised steel panels. Of this 60%, 75% of the panels are galvanised on both sides. Externally, the total number of galvanised panels rises to 90%. Galvanisation is performed using various

technological processes: The synthetic material of the inner wheelarches also has an anti-corrosive function. Box sections are protected by the use of galvanised metal panels. After painting, these are sprayed internally with wax oil to prevent internal oxidation. Areas of the bodyshell considered to be more critical are given special treatment. These include suspension, fuel tank and seatbelt mountings, and areas where mechanical components are connected to the bodyshell. SAFETY The Fiat Bravo and Fiat Brava are the result of a design and engineering project based on the most stringent all-round safety criteria, which anticipates future international legislation. Preventive safety A car's preventive safety is the sum-total of all the technical solutions and product specifications designed to make life on board relaxing and pleasant as well simple to navigate though car parks using automatic barriers. The Fiat Bravo and Fiat Brava offer an optimal driving environment carefully designed to allow the driver to exploit the potential of the engines in complete safety. The cars' ergonomic driving position has a height-adjustable steering wheel, anatomically designed seats and easy-to-reach controls. Any driver of any size can sit in comfort arid face the road in the best possible psychophysical conditions. Active safety Active safety is the sum total of the mechanical specifications which combine to improve the dynamic behaviour of the car on the road. The Fiat Bravo and Fiat Brava are the result of leading edge design. In dynamics terms this means reassuring roadholding, handling, manoeuvring and braking, whatever the conditions. This is the result of the most advanced mechanical engineering:

Passive safety Passive safety is the sum-total of the structural and product characteristics which combine to provide passengers with maximum protection in the event of an accident. Bravo and Brava bodyshells, with their controlled deformation, structural reinforcement against head-on and offset collisions, and side door impact beams, have been developed as a direct result of the most stringent crash tests. They already conform with EC legislation due to come into force in 1998 - offset impact at 34 mph (55 kph) against a deformable barrier. The rigidly structured cabin is designed as a crumple-resistant 'survival cell' reinforced by a sturdy crossbar behind the facia; by specific reinforcements to the floorpan, tunnel and longitundinals, and by side impact bars in the doors. Standard equipment also includes the following advanced safety features:

Passenger airbags are available as an option. For the protection of children on board, Fiat Lineaccessori offers an aftermarket range of EC-approved seats for all ages, weights and heights. They are notable because they:

As added safety features, the Fiat Bravo and Fiat Brava both have a third rear brake light as standard, an important safety feature which the EC proposes to make compulsory at the end of 1997. Side rubbing strips run around the perimeter of the cars to save the bodies from knocks and scratches that are always a possibility when parking in congested areas. On the Fiat Bravo and Fiat Brava, as on all the latest models produced by Fiat Auto, the concept of safety transcends the traditional preventive, active and passive areas to embrace the concept of 'owner safety'; of feeling protected against car theft. Thus, all versions of the Fiat Bravo and Fiat Brava utilise the Fiat CODE system - an ignition commutator with an electronic coded key - as standard. This engine immobiliser is both technologically sophisticated and easy to use. It operates automatically when the key is removed from the ignition. The presence of Fiat CODE means that the Fiat Bravo and Fiat Brava enjoy a particularly favourable theft insurance rating with some of the major Italian and European insurers, which has resulted in discounts of up to 30%. The system is worked by an electronic system with a specific Fiat CODE ignition key with pantographed external teeth for mechanical use (about 20,000 hard-to-reproduce combinations) and a microprocessor-transponder co-moulded into the grip. The system also includes a toroidal coil aerial, coaxial to the ignition commutator, and a specific electronic control unit hidden away in a protected, virtually inaccessible position. When activated, the microprocessor/transponder emits a radio signal with a four-digit identification code (known only to the owner of the car). Once it is picked up by the aerial, the code activates the system control unit. This, in turn, emits a signal with an unreproducible internal code to the electronic engine management system. Only if the signal is correct will the engine start. If it is not, the system deadlocks the engine. The system does, however, incorporate a recovery procedure, a specific secret code which allows the driver to start the engine even in the event of faults or breakages to the device. Safety in brief

UK RANGE AND PRICING Three versions of the Fiat Bravo and five versions of the Fiat Brava form the UK range at launch. All versions of both cars are equipped as standard with a driver's airbag, power steering, central locking, Fiat CODE immobiliser, stereo radio/cassette player, height-adjustable driver's seat, height-adjustable headlamps, height-adjustable steering wheel, pollen filter, tinted windows, air recirculation, and a third brake light. SX standard specification adds body-coloured bumpers, electric front windows, electric sunroof, split rear seat and rear seat head restraints. HLX (Bravo) and ELX (Brava) standard specification adds alloy wheels, rear spoiler (Bravo), body coloured electric door mirrors, ABS anti-lock brakes, headlamp washers, sports interior (Bravo), front fog lights, heated front seats, electric rear windows (Brava) and luxury interior (Brava). Options on both ears include ABS anti-lock brakes (standard equipment on 1.8 litre versions), passenger airbag, metallic paint, and air conditioning (ELX/HLX versions). Pricing of the Fiat Bravo and Fiat Brava is particularly competitive, and in general terms positions the ears consistently between 3% and 5% below principal competitors, version for version. However the list prices do not reflect the extent of Bravo/Brava's standard specification, which in almost all cases is notably superior. UK prices are as follows:

Options prices are as follows:

Official

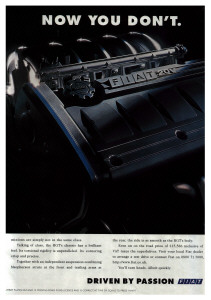

Fiat Photograph From 1995 1997 HGT Advertising (Courtesy of Si Thompson) Autocar

Review of the 147 HGT, December 1997

|